Terry W

5 Stars ⭐️⭐️⭐️⭐️⭐️

Acrylic opens up all kinds of possibilities. It’s lightweight, more transparent than glass and can be made into just about any shape imaginable. Which is why people with odd-shaped windows, from arched windows to those resembling batwings, have sought us out to make them interior storms.

Often people with unusually-shaped windows didn’t think they were ever going to be able to block drafts on that funky little round window on the second-floor landing.

And then they found us.

First we'll help you determine if inserts are the best solution for you. Next, we'll guide you step-by-step through measuring & tracing your odd-shaped windows and then custom-cut your inserts for a perfect fit. Get a free estimate today to discuss pricing and begin your order!

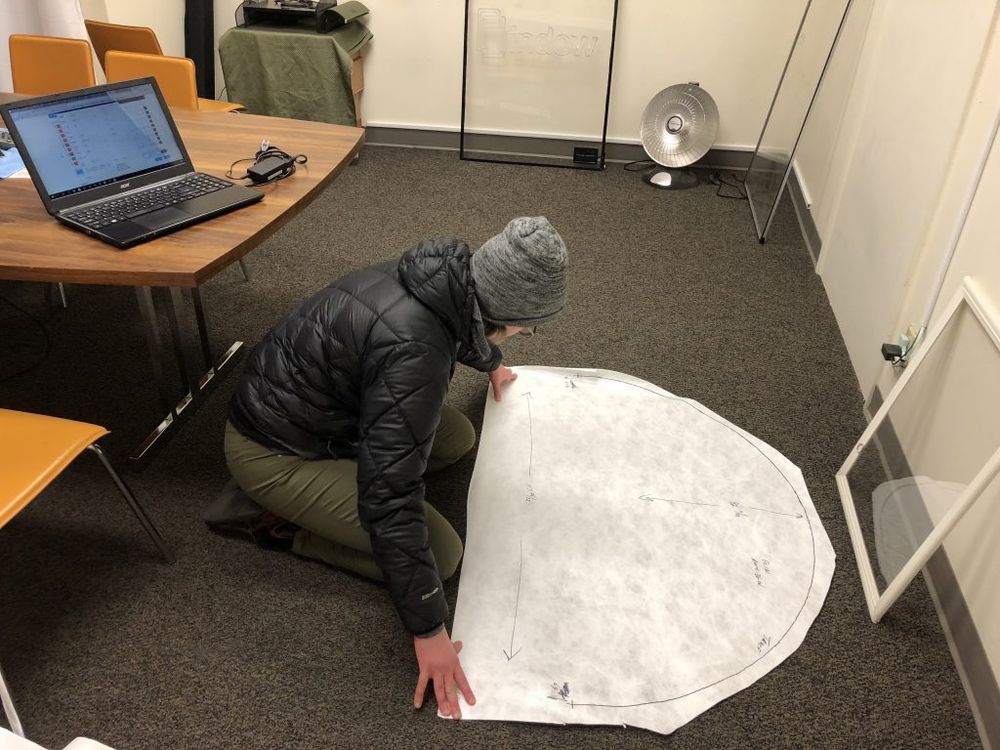

We ask people to make a template by tracing their window onto paper. Tyvek is the best, because it’s strong and light still shows through. On occasion, people will trace their odd-shaped windows onto tissue paper, but that’s prone to ripping. We don’t always need a template. Every window is different – we just try to keep the process as simple as possible.

Here’s a picture of our Operations Manager Brianna, reviewing some window templates on our conference room floor.

After we trace the shape onto acrylic, we use a circular hand saw to cut it.

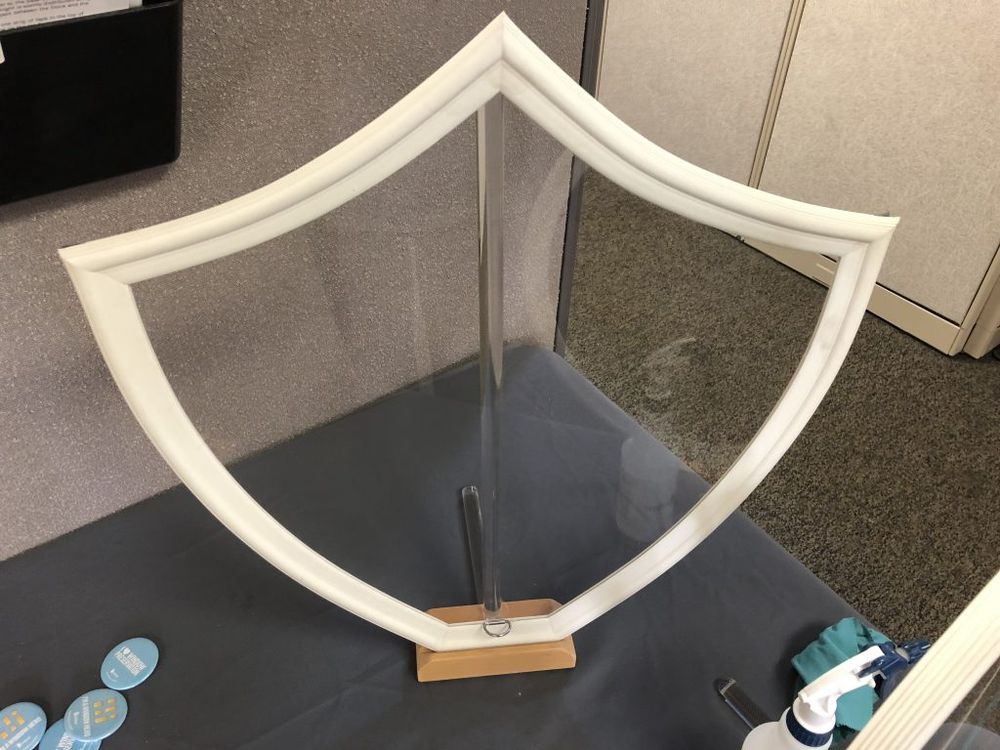

The circular saw cuts in small straight lines, kind of faceting it a little like a diamond. Then we sand that edge smooth, forming it into an arch or round, or the dips and peak of a window that resembles a fancy badge.

This is a big departure from most of the inserts we make. For normal rectangular window inserts, we input measurements into a software program that tells our Computer Numeric Control (CNC) machine how to cut the acrylic.

Also, for normal, rectangular window inserts, we use a rigid ABS (Acrylonitrile Butadiene Styrene) plastic carrier with a silicone edge. But that won’t work for shapes that dip, peak, half-round and full circle!

For custom-shaped funky windows, we have to use pure silicone tubing all around the edge, like we used to for all inserts in the old days (which was just a few years ago!) It bends and molds nicely to the edge of round window inserts.

It’s hard to find companies that make exterior or interior storms for odd-shaped windows. It’s labor-intensive to craft them of metal or wood, which makes them expensive. Plus, they’re hard to remove and put in.

“People are just generally surprised to find we do it at all,” said Brianna. “A lot of companies don’t. People tend to be surprised by how nicely they fit. They disappear into the frame.”

Have a funky window? We would love to see it! Share with us on social media on Facebook, Instagram or Twitter.

Oh, and did we mention that these odd-shaped windows come in all our grade types, from Privacy to our UV-blocking Museum Grade? Check out our product pages to customize your order.

We’re happy to discuss your odd-shaped windows! Contact us here.

Indow has insulated more than 23,000 buildings - helping reduce carbon emissions by nearly 200,000 tons - and creating comfort across the US & Canada!

The indow window company and their staff are great Partners in battling the cold winter drafts coming through your windows and helps keep your home warm and cozy.. Wonderful company and great customer service..