Stephen W

5 Stars ⭐️⭐️⭐️⭐️⭐️

Excellent product, support, and very clear instructions. We look forward to installing these on all our windows.

We use compression seals for windows because it’s simply the best way to seal against drafts and noise. The silicone in our compression system stands up to heat and sun while nearly disappearing into the window frame. It was designed with a refrigerator magnetic seal in mind, but improved and simplified to make it stronger and easier to remove and reinstall.

We use acrylic panels surrounded by silicone tubing to create our one of a kind window inserts. We use acrylic because it’s better for thermal and sound control than glass. We use silicone because it’s the best quality: long-lasting and resilient so it won’t lose its spring force over time.

Just like the Ove Glove, which uses silicone to protect your hands in the oven and keep the glove from being altered by heat, your window insert frames will stand up to the elements. They’ll be exposed to sun, heat, and UV rays for years, but will never change shape or lose their compression force.

“Silicone is almost impervious to UV radiation which exists in abundance in window frames, it’s highly resistant so it’s not going to lose its spring force over time. There’s something in engineering called compression set which is how much something loses its spring force when it’s squeezed for a long time and silicone has the very best compression set properties and durability properties.” -Sam Pardue, Indow Founder

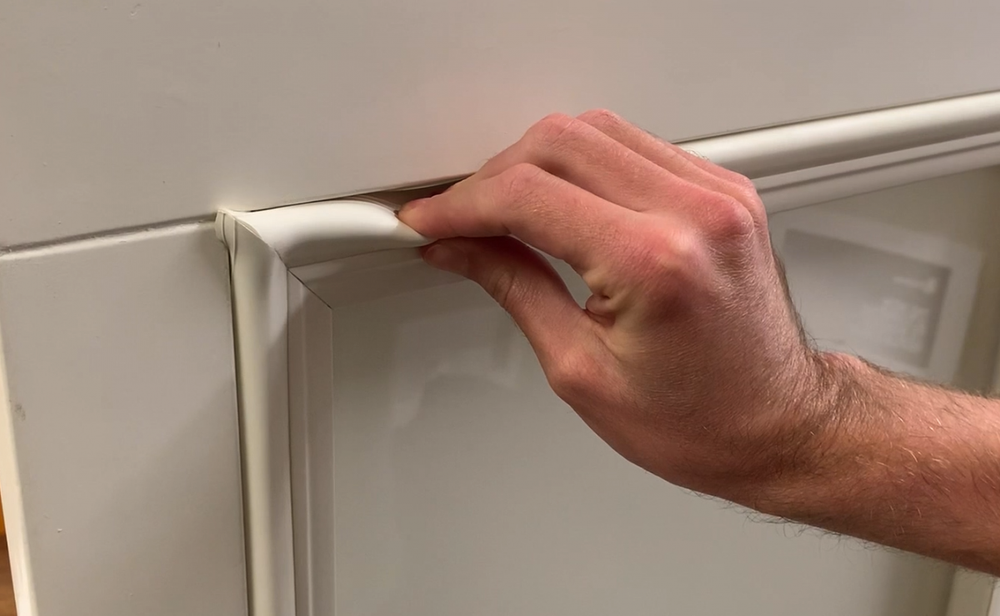

Founder and CEO Sam Pardue installing one of the first Indow inserts sold, in the first year of the company’s history

We originally had a magnet inside our tubing to seal windows. We wanted to improve the magnetic attachment system by accommodating for the acrylic panel’s thermal expansion and contraction while cleaning up the appearance by removing the need for a big metal frame on the window.

The plan was to make the frame of the insert act like a refrigerator magnetic seal. If you look at a refrigerator door, it’s a magnet surrounded by a compression seal. So, we were going to combine a magnet and compression tubing, just like a refrigerator magnetic seal.

VP of Marketing, Kristina Damschen Spina, installing the insert in the kitchen where the product was invented.

The initial prototype failed. It also didn’t look great. We removed the magnet and just used the spring force of the compression seal and worked! It looked so pristine in the window frame you could hardly see it. We accomplished everything we wanted: a near airtight seal for windows, a near perfect appearance, and no harm done to the window frame.

We didn’t stop there. We continued to innovate on the perfect way to seal windows, adding more compressive range and increasing the amount of spring force. We even added space in the tubing for a metal spine for added stability on large inserts. We’re constantly optimizing different aspects of our window insert from compression seals for windows to customer usability.

We continuously improve our compression seal for windows to create the best draft- and noise-blocking window inserts possible. Together acrylic and silicone forge a perfect sound and climate control combination. They are both resilient, standing up to sun exposure without losing their effectiveness.

No matter what window issue you have, there is a window insert that can help. Take a look at all of our products to see what works for your situation.

Indow has insulated more than 23,000 buildings - helping reduce carbon emissions by nearly 200,000 tons - and creating comfort across the US & Canada!

I ordered the "acoustic grade inserts" for my bedroom to reduce road noise. They work exactly as advertised. Are they soundproofing? NO. Do they reduce noise to acceptable levels? YES. Compared to other solutions on the market (replacement windows, glass inserts etc) this is much more affordable. However, if you are looking for actual soundproofing, you need to spend more money and get something else. As a bonus, the inserts are tight fitting and have reduced drafts.